Screw Jack Manufacturer

A screw jack is a device used to convert rotary motion into linear motion and incorporates a lead screw or ball screw to aid in this conversion. They are ideal for applications that require lifting, lowering, tilting, moving or holding.

Strength

Reliability

Flexibility.

Main Performance Advantages of Screw Jack

A screw jack is a mechanical device used to transport and lift objects vertically. It has many performance advantages, including:

Vertical lifting ability

The screw jack can effectively lift objects vertically to the desired height. Capable of handling large amounts of weight and objects of various sizes, they provide a flexible lifting solution.

High space utilization

Screw jacks are usually designed in a spiral shape, which allows them to operate in a small space. They take up less floor space than other conventional lifts, making them easier to install and use in confined spaces.

Safe and reliable

Screw jacks usually have multiple safety protection devices, such as limit switches, overload protection, etc., to ensure safety during operation. They are designed and manufactured to strict safety standards, reducing the risk of accidents and damage.

Energy saving and environmental protection

Screw jacks usually use electric or hydraulic drive systems, which have low energy consumption. They use energy more efficiently than conventional lifts, reducing energy waste and environmental impact.

Versatility

Screw jacks can be used in various application scenarios, including industrial production lines, storage equipment, logistics and transportation, etc. They can be custom designed on demand to suit different object lifting requirements.

What Are Screw Jack?

A screw jack is a mechanical device used for lifting or lowering heavy loads or applying force in a linear motion. It consists of a threaded screw and a mating nut. When the screw is rotated, the nut moves along the screw’s threads, resulting in vertical movement or force application. Screw jacks often incorporate a worm gear or bevel gear mechanism to provide the rotary motion to the lifting screw. They are commonly used in industries such as construction, automotive, and manufacturing, where precise and controlled lifting or force application is required. Screw jacks offer a mechanical advantage and can handle substantial loads, making them valuable tools in various applications.

Screw Jack for Sale

As a screw jack manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Screw Jack Application Industry

Screw jacks find applications in various industries where heavy loads need to be lifted, lowered, or positioned. Here are some industries that commonly use screw jacks:

Aerospace Industry

Screw jacks are employed in the aerospace industry for tasks such as adjusting the position of aircraft components, supporting maintenance platforms, and positioning satellite antennas.

Entertainment Industry

In the entertainment industry, screw jacks are used for stage setups, lighting rigs, and moving heavy equipment such as speakers, video screens, and theatrical props. They provide precise control over the height and positioning of various stage elements.

Renewable Energy

Screw jacks find application in the renewable energy sector, particularly in solar panel installations. They are used to adjust the tilt angle of solar panels to optimize their exposure to sunlight throughout the day.

Shipbuilding

Screw jacks are utilized in shipyards for tasks such as lifting and aligning ship components, adjusting dock gates, and supporting heavy loads during the construction and maintenance of ships.

Mining and Heavy Equipment

Screw jacks are employed in the mining industry for lifting and positioning heavy machinery, adjusting conveyor systems, and supporting mining equipment during maintenance and repair operations.

Oil and Gas Industry

Screw jacks are utilized in the oil and gas industry for tasks such as lifting and positioning heavy equipment, adjusting valves, supporting drilling platforms, and performing maintenance on pipelines and offshore structures.

Railway and Transportation

Screw jacks are used in railway and transportation applications for tasks such as adjusting the height of railway tracks, aligning switches and signals, supporting maintenance equipment, and lifting and leveling platforms for loading and unloading cargo.

Civil Engineering

In civil engineering projects, screw jacks are employed for tasks such as lifting and adjusting bridge components, supporting temporary structures during construction, adjusting the height of building foundations, and aligning heavy precast concrete elements.

Warehousing and Logistics

Screw jacks find application in warehouses and logistics operations for tasks such as adjusting conveyor systems, lifting heavy pallets or goods, and supporting equipment for material handling and storage.

Power Generation

Screw jacks are used in power generation facilities for various purposes, including adjusting the position of turbine components, supporting maintenance platforms, and lifting heavy machinery during installation or repair.

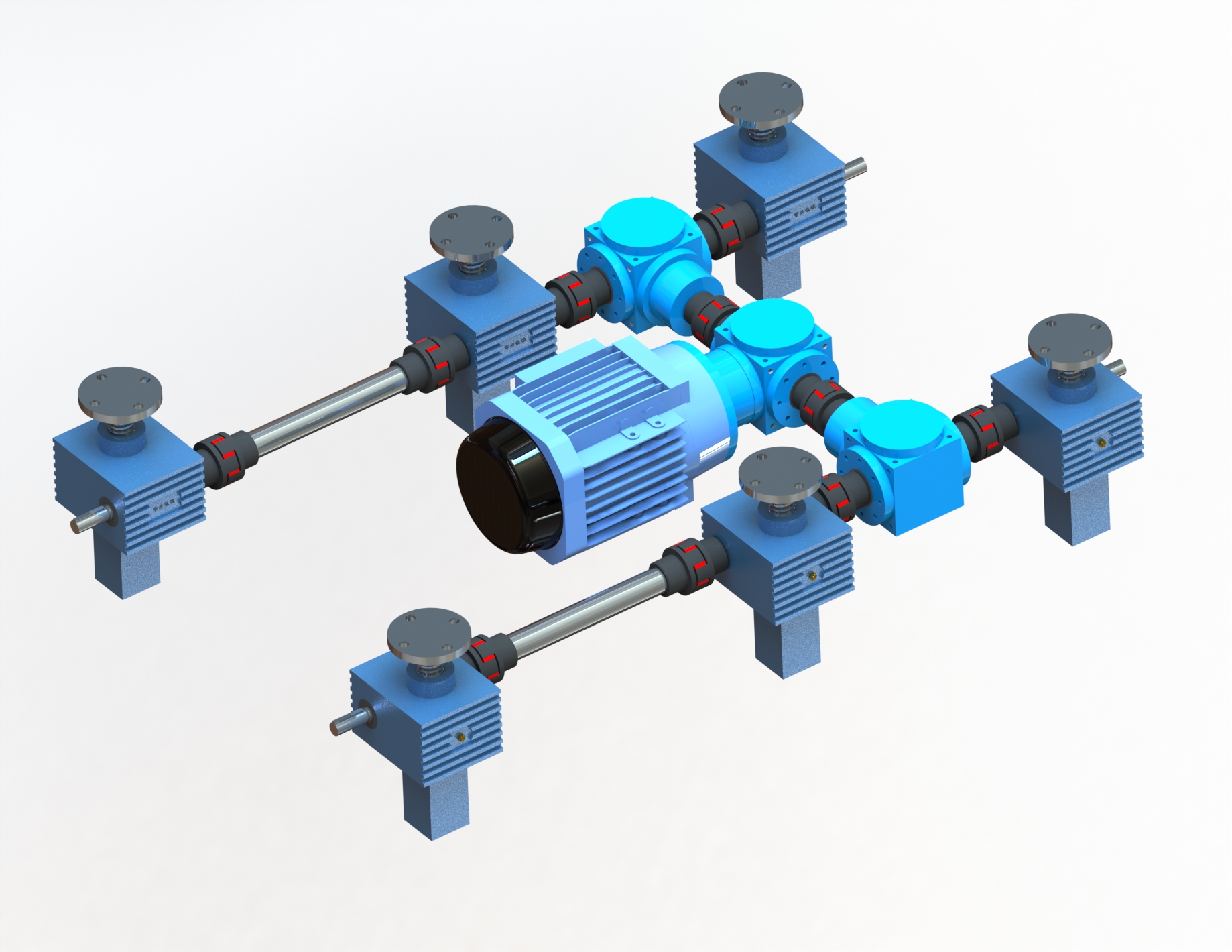

Screw Jack Types

Screw jacks are mechanical devices used to lift heavy loads or apply force through the conversion of rotary motion into linear motion. There are several types of screw jacks available, each designed for specific applications. Here are some common types:

Worm Gear Screw Jack

This is the most common type of screw jack. It consists of a worm gear mechanism that drives a lifting screw. The worm gear provides a high gear ratio, allowing for high load capacities and precise positioning. It is commonly used in industrial machinery, construction, and automotive applications.

Ball Screw Jack

This type of screw jack incorporates a ball screw mechanism instead of a traditional lifting screw. The ball screw provides greater efficiency, reduced friction, and increased speed compared to a standard screw jack. It is commonly used in applications where high precision and high-speed operation are required, such as CNC machines and robotics.

Machine Screw Jack

This type of screw jack uses a machine screw as the lifting mechanism. It typically has a smaller load capacity compared to worm gear or ball screw jacks but is more compact and cost-effective. Machine screw jacks are commonly used in applications such as adjustable worktables, height-adjustable platforms, and small-scale lifting systems.

Stainless Steel Screw Jack

These screw jacks are constructed using stainless steel components, making them suitable for applications where corrosion resistance is required. They are commonly used in environments with high humidity, chemical exposure, or food processing industries.

Features of Screw Jack

Screw jacks possess several notable features that make them useful for a wide range of applications. First, they offer a high mechanical advantage, allowing for the lifting or lowering of heavy loads with relatively low input force. This mechanical advantage is achieved through the use of a threaded screw and nut, which convert rotary motion into linear motion. Second, screw jacks provide precise and controlled movement. The threads on the screw enable fine adjustments and positioning of the load, making them suitable for applications requiring accuracy. Third, they are typically designed for heavy-duty use and have high load-bearing capacities. This makes screw jacks capable of handling substantial weights and providing reliable support. Additionally, screw jacks can be customized to fit specific requirements, such as different lifting capacities, speeds, and power transmission methods. Their versatility, strength, and precise operation make screw jacks indispensable in industries ranging from construction and manufacturing to automotive and aerospace.

How Does a Screw Jack Work

A screw jack works on the principle of converting rotary motion into linear motion to lift or lower heavy loads or apply force. Here’s a simplified explanation of how a screw jack works:

Components: A screw jack consists of several key components. These include a threaded screw (lifting screw), a mating nut, and often a gear mechanism (such as a worm gear or bevel gear) to provide the rotational motion to the screw.

Threaded Screw and Nut: The threaded screw has helical threads along its length, and the nut has a corresponding threaded hole that engages with the screw. When the screw is rotated, the nut moves linearly along the screw’s threads.

Gear Mechanism: In most screw jacks, a gear mechanism is used to convert rotary motion into the rotational motion of the screw. For example, in a worm gear screw jack, a worm gear (a threaded gear) is rotated by an input shaft, which drives the worm wheel (a mating gear) that is connected to the lifting screw. As the worm wheel rotates, it causes the screw to rotate.

Industry case

Bottle Jack VS Screw Jack

Bottle jacks and screw jacks are two common types of mechanical jacks used for lifting heavy loads, but they differ in their design, operation, and specific applications.

A bottle jack is a hydraulic jack that utilizes hydraulic pressure to lift the load. It consists of a cylindrical body (resembling a bottle) with a hydraulic ram piston inside. When pressure is applied to the hydraulic fluid, it pushes against the piston, causing it to extend and lift the load. Bottle jacks are compact, portable, and capable of lifting heavy loads with relatively small physical effort. They are commonly used in automotive repairs, construction, and general maintenance tasks.